When it comes to safeguarding hardworking hands, TECHACS Safety Solutions stands out as the industry leader. Our hand protection range is meticulously crafted with precision and the highest-quality materials, ensuring the perfect balance of protection, comfort, and functionality. Whether you’re tackling heavy-duty industrial tasks or handling delicate operations, TECHACS has the right gloves for every application.

In this guide, we’ll explore the materials, performance factors, and industry standards that make TECHACS gloves the best defense for hardworking hands.

Hand Protection Materials: Precision Engineered for Every Task

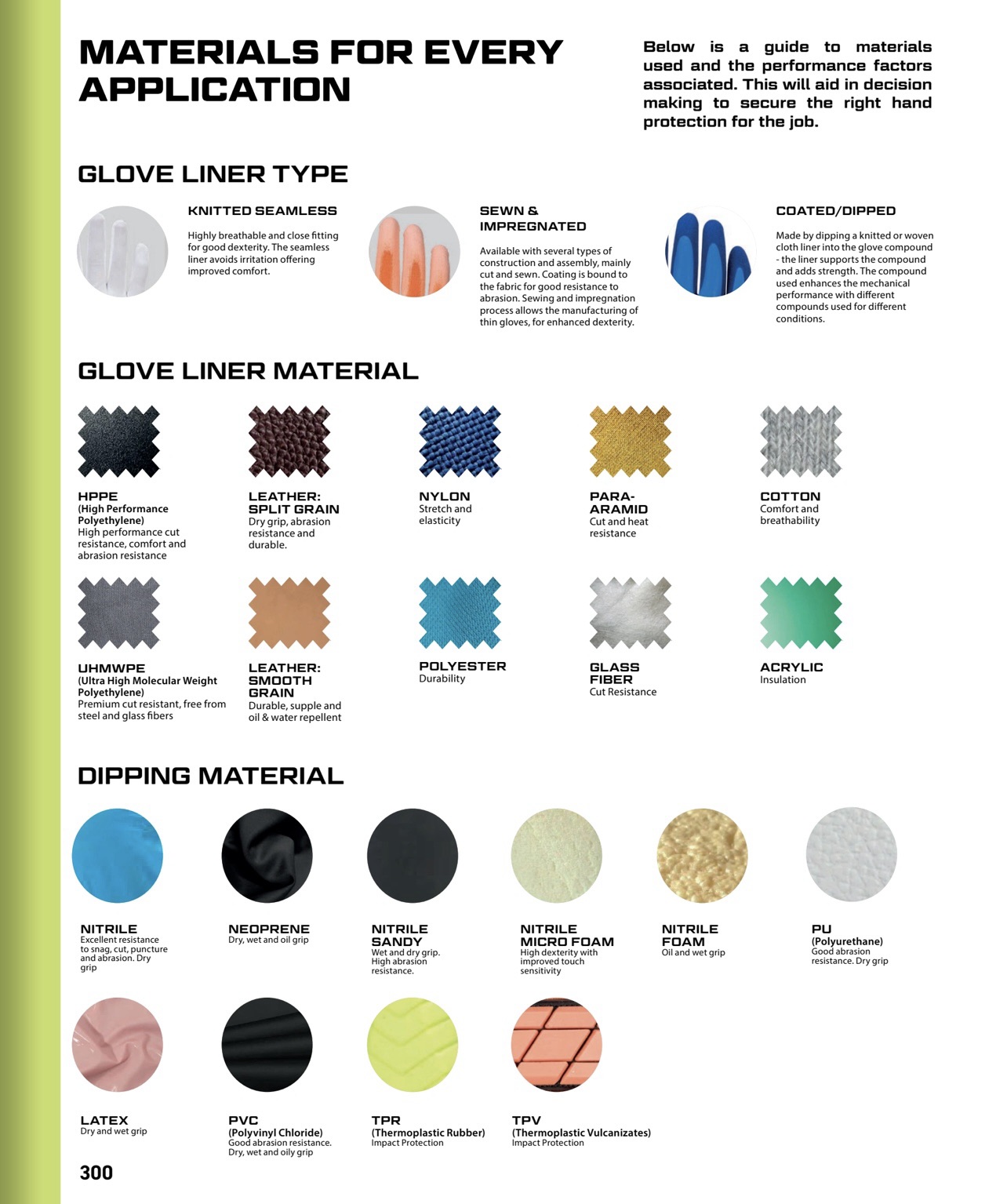

Choosing the right glove starts with understanding the materials. TECHACS offers a diverse range of glove liners and coatings, each designed to meet specific performance needs.

Glove Liner Types

- Knitted Seamless

- Highly breathable and close-fitting for superior dexterity.

- Seamless design minimizes irritation, enhancing comfort during prolonged use.

- Sewn & Impregnated

- Cut-and-sewn construction with coatings bound to the fabric for excellent abrasion resistance.

- Ideal for thin gloves that prioritize dexterity without compromising protection.

- Coated/Dipped

- Knitted or woven liners dipped in specialized compounds for enhanced mechanical performance.

- Compounds are tailored to specific conditions, ensuring optimal grip and durability.

Glove Liner Materials

- HPPE (High-Performance Polyethylene):Exceptional cut resistance, comfort, and abrasion resistance.

- Leather (Split Grain): Offers dry grip, durability, and abrasion resistance.

- Nylon: Provides stretch and elasticity for a snug fit.

- Para-Aramid: Delivers cut and heat resistance for high-risk environments.

- Cotton: Ensures comfort and breathability for light-duty tasks.

- UHMWPE (Ultra-High Molecular Weight Polyethylene): Premium cut resistance without steel or glass fibers.

- Leather (Smooth Grain): Durable, supple, and resistant to oil and water.

- Polyester: Known for its durability and long-lasting performance.

- Glass Fiber: Excellent cut resistance for heavy-duty applications.

- Acrylic: Provides insulation for cold environments.

Dipping Materials

- Nitrile: Superior resistance to abrasion and chemicals, with excellent dry grip.

- Neoprene: Reliable grip in dry, wet, and oily conditions.

- Nitrile Sandy: High abrasion resistance with wet and dry grip.

- Nitrile Micro Foam: Enhances dexterity and touch sensitivity.

- Nitrile Foam: Ideal for oil and wet grip applications.

- PU (Polyurethane): Good abrasion resistance and dry grip.

- Latex: Offers reliable dry and wet grip.

- PVC (Polyvinyl Chloride): Resists abrasion and provides grip in dry, wet, and oily conditions.

- TPR (Thermoplastic Rubber): Designed for impact protection.

- TPV (Thermoplastic Vulcanizates):Combines durability with flexibility.

Industry Standards: Ensuring Unmatched Protection

TECHACS gloves are rigorously tested to meet and exceed industry standards, ensuring they deliver the highest level of protection.

ANSI/ISEA 138-2019

- Impact-Resistant Gloves: This standard classifies gloves based on their ability to protect against impact. Gloves are tested by dropping a 5-joule mass on the knuckles and fingers, with results averaged to determine performance levels (1, 2, or 3).

ASTM F2675-13

- Arc Flash Protection: Measures the arc thermal performance value (ATPV) of gloves, ensuring they provide adequate protection against electrical arc flashes.

ANSI/ISEA 105

- Hand Protection Classification:Categorizes gloves based on their performance in cut resistance, puncture resistance, abrasion resistance, and more.

Performance Levels Explained

Cut Resistance (ASTM F2992-15)

- Gloves are tested with a straight-edge blade under load, with results classified from A1 to A9. Higher levels indicate greater cut resistance.

Puncture Resistance

- Gloves are rated based on the force required to puncture the material, with levels ranging from 1 to 5.

Abrasion Resistance

- Tested using abrasion cycles, gloves are classified from level 0 to 6, with higher levels indicating greater durability.

Chemical Permeation Resistance

- Gloves are tested for their ability to resist chemical permeation, with breakthrough times classified from level 0 to 6.

Heat and Flame Protection

- Gloves are rated for ignition resistance, burning behavior, and conductive heat resistance, ensuring they can withstand high temperatures.

Why Choose TECHACS Safety Solutions?

At TECHACS, we understand that hardworking hands deserve the best protection. Our gloves are designed to meet the demands of diverse industries, from construction and manufacturing to electrical work and chemical handling. With a commitment to quality, innovation, and safety, TECHACS is your trusted partner in hand protection.

Protect Your Hands with TECHACS – Because Every Hand Deserves the Best Defense.

Visit www.techacs.com to explore our full range of hand protection solutions and find the perfect gloves for your needs.